Ankit Kumar 2025-07-30

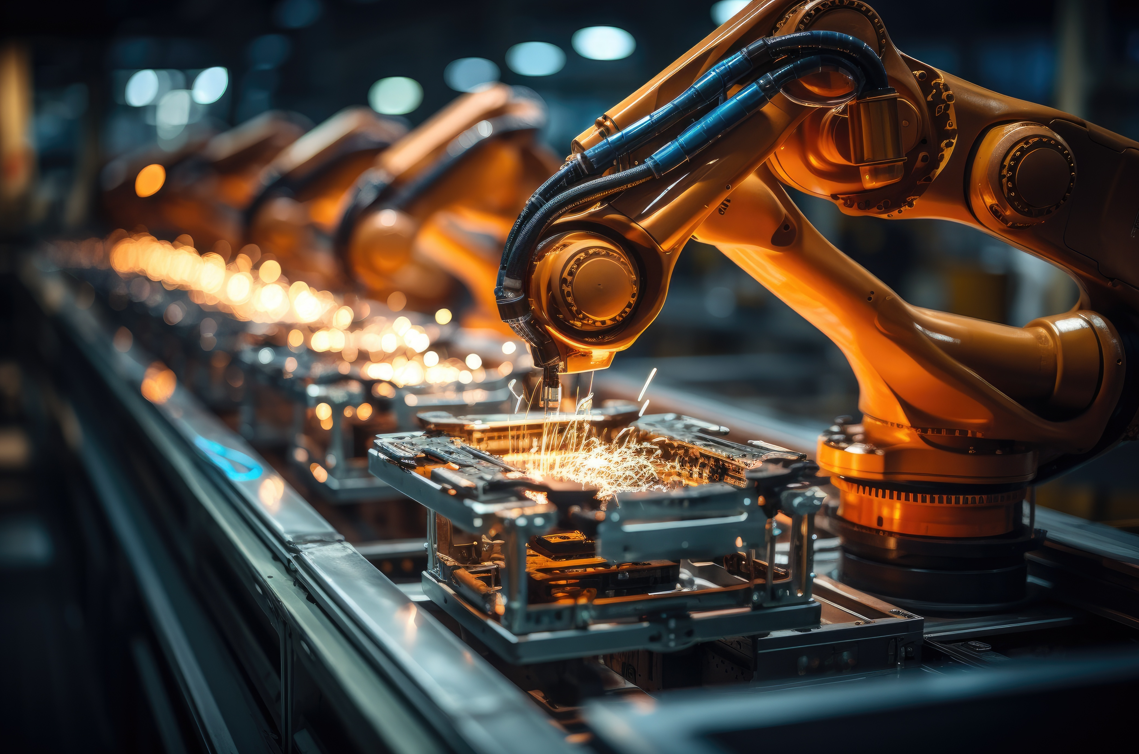

The manufacturing sector, a cornerstone of global economies, is undergoing a profound transformation driven by Artificial Intelligence (AI). This technological revolution, often referred to as Industry 4.0, is reshaping traditional production processes, supply chains, and operational efficiencies. The adoption of AI in the manufacturing industry is no longer a theoretical concept but a tangible reality, offering unprecedented opportunities for innovation and growth. From optimizing complex production lines to enhancing product quality and reducing operational costs, AI is proving to be a critical enabler of productivity gains.

In an increasingly competitive global landscape, manufacturers face constant pressure to innovate, reduce lead times, and deliver high-quality products at lower costs. AI provides the tools necessary to address these challenges. By leveraging advanced algorithms and machine learning, manufacturers can gain deeper insights into operations, predict potential issues, and automate tasks that were once labor-intensive. This shift towards intelligent automation creates more resilient, adaptive, and responsive manufacturing ecosystems.

This article will delve into the multifaceted impact of AI on the manufacturing sector. We will explore how AI in manufacturing industry is driving significant productivity gains, examining key applications and real-world examples. Furthermore, we will discuss the current state of the artificial intelligence in manufacturing market, highlighting its growth trajectory and the diverse range of AI solutions for manufacturing that are becoming indispensable. By understanding these transformative applications, manufacturers can better position themselves to harness the full potential of AI, ensuring sustained growth and a competitive edge.

AI integration into manufacturing has moved beyond experimental stages to become a strategic imperative. The artificial intelligence in manufacturing market is experiencing robust growth, driven by the tangible benefits of AI in manufacturing that extend across the entire value chain. From predictive maintenance to quality control and supply chain optimization, AI is proving its worth by delivering measurable improvements in efficiency, cost reduction, and product quality.

Industry 4.0 has laid the groundwork for AI's widespread adoption. Manufacturers recognize that to remain competitive, they must embrace smart factories powered by AI. This involves leveraging vast amounts of data from connected machines, sensors, and systems to gain actionable insights. The market for AI solutions for manufacturing is expanding rapidly, with diverse tools and platforms designed to address specific industry challenges. These solutions enable manufacturers to move from reactive to proactive strategies, anticipating issues and optimizing operations in real-time.

Despite the clear advantages, full AI integration faces challenges like data quality, skill gaps, and legacy system integration. However, the overwhelming evidence of AI's positive impact, including significant productivity gains and enhanced decision-making, continues to drive investment and innovation. The current landscape is one of rapid evolution, where early adopters are reaping substantial rewards, setting a precedent for the broader industry.

The transformative power of AI in manufacturing is best understood through its tangible benefits of AI in manufacturing. These advantages represent fundamental shifts in how manufacturing operations are conceived and executed, leading to significant productivity gains and competitive differentiation.

One of the most immediate and impactful benefits of AI in manufacturing is its ability to revolutionize quality control. AI-powered vision systems achieve significantly higher accuracy rates by learning from vast datasets of product images, identifying minute defects. AI can predict and prevent defects, ensuring consistent product quality, reducing waste, and minimizing costly recalls. Companies leverage AI solutions for manufacturing for real-time defect detection, allowing immediate adjustments on the production line.

Machine downtime is a major impediment to productivity. AI addresses this through predictive maintenance, anticipating equipment failures. By monitoring sensor data, AI algorithms detect anomalies indicative of impending issues. This allows maintenance teams to schedule interventions precisely when needed, minimizing unplanned downtime and extending asset lifespan. The economic benefits of AI in manufacturing are substantial, shifting maintenance to a proactive, cost-saving strategy. This is a prime example of how AI in manufacturing industry optimizes operational efficiency.

AI-driven optimization transforms complex manufacturing supply chains. AI analyzes data related to demand, supplier performance, logistics, and geopolitical factors for accurate forecasts. This enables manufacturers to optimize inventory, reduce costs, and prevent stockouts. AI can identify potential disruptions, allowing contingency plans. The ability of AI solutions for manufacturing to provide end-to-end visibility and intelligent recommendations enhances supply chain resilience and responsiveness, leading to improved delivery times.

AI enhances overall production efficiency. By analyzing real-time production data, AI algorithms identify bottlenecks, optimize machine parameters, and streamline workflows. This leads to increased throughput, reduced energy consumption, and efficient resource allocation. AI-powered simulation tools model production scenarios, allowing virtual testing before physical implementation. This iterative optimization, driven by AI in manufacturing industry, ensures peak performance, maximizing output and minimizing waste. These improvements contribute significantly to the overall benefits of AI in manufacturing.

The theoretical benefits of AI in manufacturing are powerfully illustrated by real-world applications. These examples demonstrate how diverse AI solutions for manufacturing are deployed to solve complex problems and drive tangible results.

BMW Group: Precision in Quality Control

BMW Group integrates AI into its quality control. An AI application compares vehicle order data with live images of new cars, focusing on model designations. By cross-referencing with a database, the AI spots deviations, ensuring stringent quality standards. This is a prime example of how AI in manufacturing industry is used for precision and quality assurance.

Canon: Augmenting Human Capabilities

Canon uses Assisted Defect Recognition (ADR), an advanced AI solution for manufacturing combining machine learning, computer vision, and predictive analytics. ADR examines parts using X-ray and images to assess internal structure. It identifies defects, even those invisible to the human eye, and improves accuracy based on human corrections. This collaborative approach highlights how AI in manufacturing industry enhances human performance.

Jabil: AI for Trade Compliance and Process Optimization

Jabil deploys AI for trade compliance code identification, improving accuracy and efficiency in a previously manual process. Jabil also applies AI solutions to injection molding machines, analyzing parameters to optimize molding quality. These applications demonstrate the practical benefits of AI in manufacturing in streamlining processes and ensuring regulatory adherence.

These examples underscore the versatility and profound impact of AI in manufacturing industry. From quality control to process optimization, AI is an indispensable tool for driving productivity gains and operational excellence. The strategic adoption of these AI solutions secures a competitive edge.

While the benefits of AI in manufacturing are compelling, successful implementation faces challenges. Proactive addressing is crucial for maximizing ROI.

Data Quality and Integration

AI systems rely on quality data. In manufacturing, data often resides in disparate systems, is inconsistent, or lacks quality. Integrating diverse sources and ensuring data cleanliness is a challenge. Solutions involve robust data infrastructure, governance policies, and data preparation tools. For complex needs, an enterprise AI development firm provides expertise.

Skills Gap and Training

AI's rapid evolution creates a skills gap. There's a shortage of AI, machine learning, and data science experts. Manufacturers must invest in upskilling existing workforce and collaborate with external specialists or an enterprise AI development company. Fostering continuous learning is essential for integrating AI in manufacturing industry.

ROI Considerations

Demonstrating clear ROI for AI initiatives can be challenging initially. Benefits like improved efficiency may not translate directly into immediate financial gains. Manufacturers need clear metrics and KPIs. Starting with pilot projects in high-impact areas can demonstrate value. A well-defined strategy, often with an enterprise AI development partner, helps articulate long-term value.

Ethical Considerations and Bias Mitigation

AI's pervasiveness raises ethical concerns, particularly regarding bias and workforce impact. Manufacturers must develop and deploy AI responsibly, adhering to ethical guidelines and mitigating biases. This involves diverse training datasets, transparent models, and regular audits. Engaging with an enterprise AI development company specializing in ethical AI helps navigate these issues. Responsible deployment of AI in manufacturing industry is paramount.

Future Trends and Opportunities

The trajectory of AI in manufacturing industry points towards an even more integrated and intelligent future. Several key trends will further revolutionize the sector, building upon the foundational benefits of AI in manufacturing.

Hyper-Personalization and Mass Customization

Future AI will enable unprecedented product personalization. AI-powered design tools and flexible manufacturing systems will allow efficient production of unique items tailored to individual preferences. This will drive the artificial intelligence in manufacturing market.

AI-Powered Robotics and Automation

Collaboration between humans and robots will become more seamless. AI will enhance robotic capabilities, enabling complex tasks and learning from human interactions. This will lead to highly automated factories, amplifying the benefits of AI in manufacturing.

Digital Twins and Simulation

Digital twin technology will integrate with AI. Virtual replicas of assets and processes will allow manufacturers to simulate production lines, test designs, and predict performance. AI will analyze simulation data to optimize processes before physical implementation. These advanced AI solutions will become standard.

Edge AI and Decentralized Intelligence

Processing AI algorithms closer to the data source (edge) will become prevalent. This reduces latency, enhances security, and enables real-time decision-making on the factory floor without heavy reliance on cloud. This decentralized approach will unlock new possibilities for autonomous operations, expanding AI in manufacturing industry.

Sustainable Manufacturing

AI will play a crucial role in sustainable manufacturing. By optimizing energy consumption, minimizing waste, and improving resource utilization, AI helps reduce environmental footprint. AI-powered analytics identify inefficiencies, offering insights for eco-friendly operations. This focus on sustainability will be a growing area for AI solutions for manufacturing.

These trends paint a picture of a manufacturing future that is highly intelligent, adaptive, and efficient, continually pushing boundaries through AI.

The integration of AI into the manufacturing sector represents a transformative shift, fundamentally reshaping how products are designed, produced, and delivered. As we have explored, the benefits of AI in manufacturing are extensive, ranging from enhanced quality control and predictive maintenance to optimized supply chains and increased production efficiency. AI is not merely an incremental improvement; it is a catalyst for unprecedented productivity gains, enabling manufacturers to navigate challenges and seize opportunities.

For businesses seeking to harness the full potential of AI in manufacturing industry, strategic implementation is paramount. This involves addressing data quality, talent acquisition, and ethical considerations. However, the long-term advantages of adopting advanced AI solutions far outweigh initial hurdles, promising a future where factories are smarter, more agile, and inherently more efficient.

The future of manufacturing is intelligent, driven by AI. As the artificial intelligence in manufacturing market expands, companies that proactively invest in AI and foster innovation will lead. This journey requires strategic vision and expertise.

Navigating AI integration, from custom solutions to seamless deployment, can be daunting. Specialized partners are invaluable. Companies like Es Magico are at the forefront of providing comprehensive enterprise AI development services, tailored for manufacturing. As a leading enterprise AI development company, Es Magico empowers manufacturers to unlock AI's full potential, transforming operations, enhancing competitive edge, and securing a prominent position in the intelligent manufacturing era. Partnering with such experts ensures a successful and impactful AI journey, setting new benchmarks for innovation and efficiency.

Share On:

Discover how AI is transforming the retail industry with 10 powerful use cases—from personalized shopping to intelligent inventory and dynamic pricing. Learn how businesses can harness AI for efficiency, customer engagement, and growth.

Explore the top 10 AI solutions transforming the BFSI industry in 2025. Discover how AI is driving personalization, fraud prevention, risk management, and innovation in finance.

How AI is transforming smart manufacturing and industrial automation. Learn real-world benefits, use cases, and how Es Magico empowers businesses with AI solutions for the future of industry.